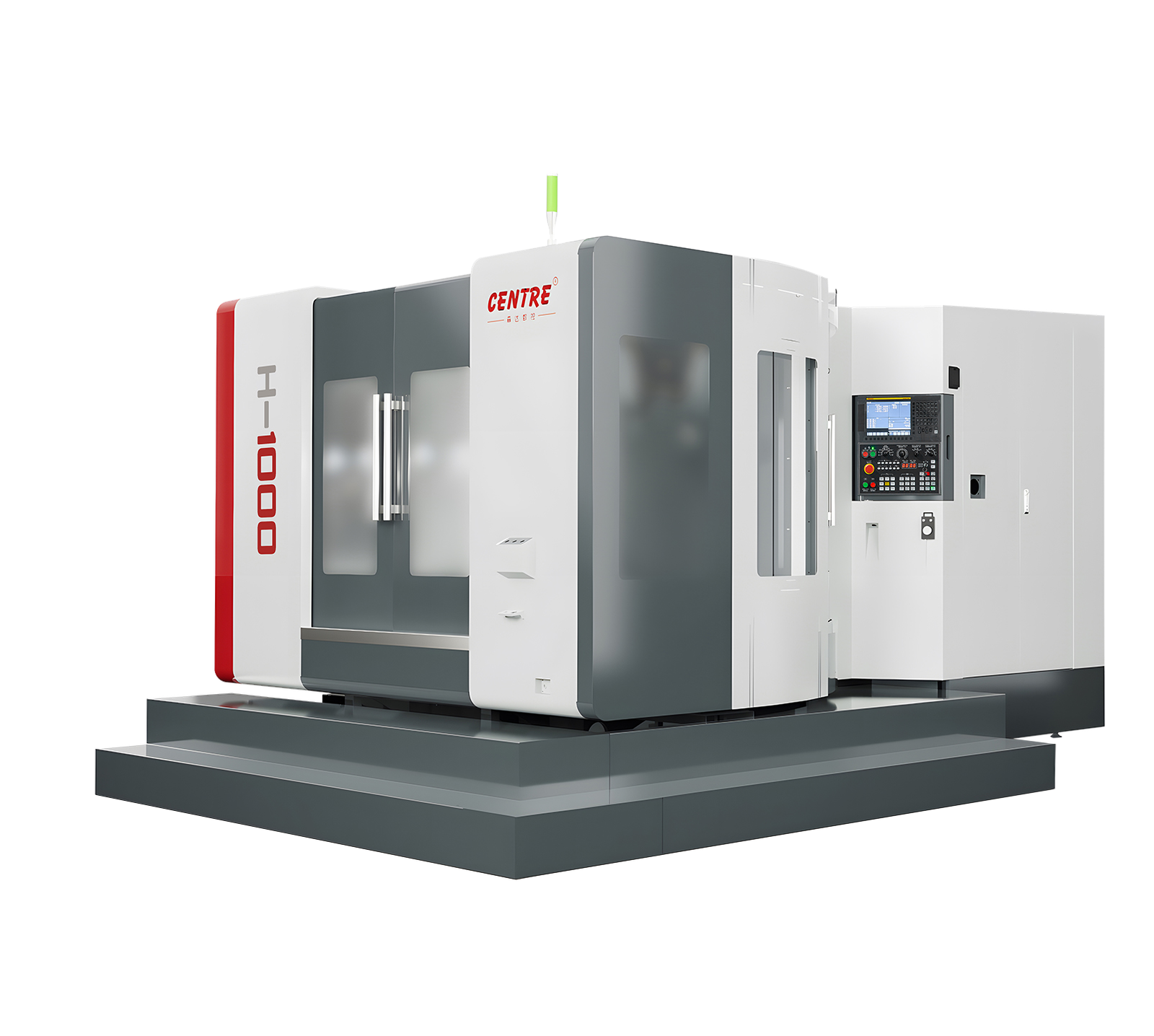

H-1000

Caracteristici principale

Inverted T-shaped moving column design and one-piece machine body structure

Resin sand casting

Spiral Conveior de șpan interface and cutting scouring device

Centralized Lubricant Recovery System

The ball screw with pre-stretched structure and lubricated with thin oil

V3 level heavy-duty linear ball rail

Vertical downward armor protection and shield of Z-direction guideway

Upright column and top enclosed protection

Specificații tehnice

Cursă

Deplasarea pe axe(X/Y/Z): 1600/1000/1000 (mm)

Distanta de la centrul mesei la punctul de referinta al spindleului: 200-1200 (mm)

Distanta de la suprafața mesei la centrul spindleului: 120-1120 (mm)

Lățimea ghidajelor pe cele 3 axe (X/Y/Z): 55 (mm)

Table

Min Pallet indexing Angle: “1⁰/0.001⁰”

Suprafața mesei (Width x Length): 1000×1000 (mm)

Pallet Loading Capacity: 2000 (kg)

T-slot: 5x22x200 (mm)

Max Workpiece Swing Diameter: ф1600

Spindle

Spindle Taper: BT50

Spindle Speed: 6000 (rpm)

Spindle servo Motor: 15-22.5 (kw)

Feed

Rapid Traverse(X/Y/Z/B): 24/24/24/8 (m/min)

Max Cutting Feed Rate(X/Y/Z): 10 (m/min)

4-axis Servo Motor(X/Y/Z/B): 3/3/3/3 (kw)

BallScrewDiameter/Pitch(X/Y/Z): 50/12 (mm)

Accuracy

Positioning Accuracy: ±0.006 (mm)

Repeatability: ±0.003 (mm)

Pallet Positioning Accuracy: ±6″ (arc-sec)

Pallet Repeatability Accuracy: ±3″ (arc-sec)

Other

Electrical Power Supply: 50KVA

Machine Cover: Integral Protection

Mass of Machine: 16500 (kg)

Machine Size: 6000x4500x4100 (mm)

Sistem de comandă și Software

Mitsubishi

FANUC

Syntec

Siemens

Accesorii opționale

●ToolMagazine:32T BT50 DiskType, 40T BT50 Runway Type

●Linear Encoder:Heidenhain,Fagor

●Magazie scule indexabila

●Răcire prin spindel

●Senzor pentru detectarea ruperii sculei

●Sistem de aspirare a vaporilor de ulei

●Dispozitiv automat de măsurare a sculelor

●Conveior de șpan